Konica Minolta, the leader in high production printing (HPP) toner colour sheetfed since launching into the market little over three years ago, has unveiled the enhanced AccurioPress C14000e Series.

Launched globally in October 2019, Konica Minolta has sold more than 700 AccurioPress C14000/C12000 machines in Europe that have won several international awards and produced an estimated 8.4 billion A4 sheets in a three-year time span.

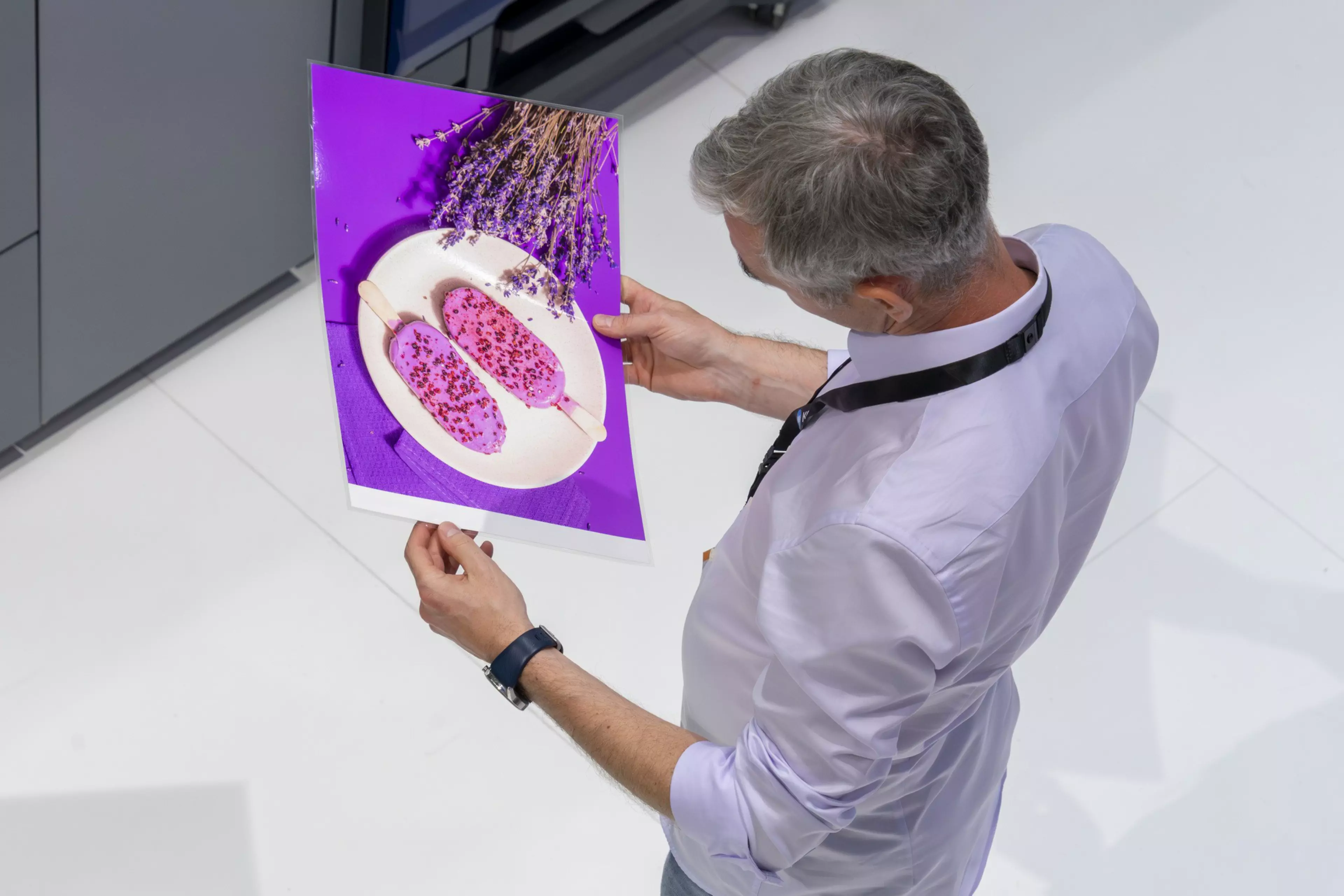

Konica Minolta has received INGEDE accreditation from the International Association of the Deinking Industry and the internationally recognised BS standard 5609 for printed pressure-sensitive, adhesive-coated labels for goods due for marine shipment. In addition, the AccurioPress C14000 and C12000 printers have been certified for their food grade safe toner, the TÜV Rheinland mark is PROOF Criteria Catalogue for Printed Papers in Contact with Foodstuff. Konica Minolta also won the “Good Design Award 2020” from the Japan Institute of Design Promotion (JDP) as well as the reddot award (winner 2021) for the machines.

The Konica Minolta

AccurioPress C14000e prints at 140 pages per minute (ppm) in A4 and is 40% faster than any other toner-based device from Konica Minolta. Together with the

AccurioPress C12000e, a second model in the series that has a speed of 120 ppm, the award-winning flagship production presses were Konica Minolta’s first foray into the high-volume toner printing segment, which has seen growth rates return to virtually pre-pandemic levels.

The improvements to the top selling AccurioPress C14000/C12000 Series follow customer feedback as Konica Minolta continues to grow its position within high production printing markets for colour toner machines.

The important new features of the Konica Minolta AccurioPress C14000e/C12000e presses include:

- Colour and imaging, productivity, management and connection upgrades through the EFI Fiery Controller Version 2.1

- Latest Firmware with dozens of software additions and improvements

- These range from Konica Minolta’s IQ-501 AQA (auto quality adjustment), RIP, media sensor and PrintManager enhancements, plus expansion of paper basis weights, banner paper support and general improved usability

- A wide range of automised finishing options to create ready-made print products that save time.