Konica Minolta has today announced the introduction of next-level production and finishing versatility to its AccurioPress systems with the new GBC CL-401 inline laminator, the world’s first inline finisher to offer lamination directly after the print process with up to 100% printer productivity.

The GBC CL-401 delivers unrivalled finished results to help customers ignite more possibilities for a broader range of digital print applications.

In combination with the Konica Minolta AccurioPress systems, the unit enables the production of laminated and ready-to-ship documents in one easy step. Currently, lamination is completed as a separate, offline process that is time-consuming, manual and cost-intensive.

Smooth, seamless and fast production is made possible with the GBC CL-401 innovative cold lamination process. The elimination of warm-up times and the direct, two side, application process saves time. Cold lamination also offers the option of laminating only one side of a graphic, perfect for decals and adhesive decorations.

Fresh approach reimagines production versatility

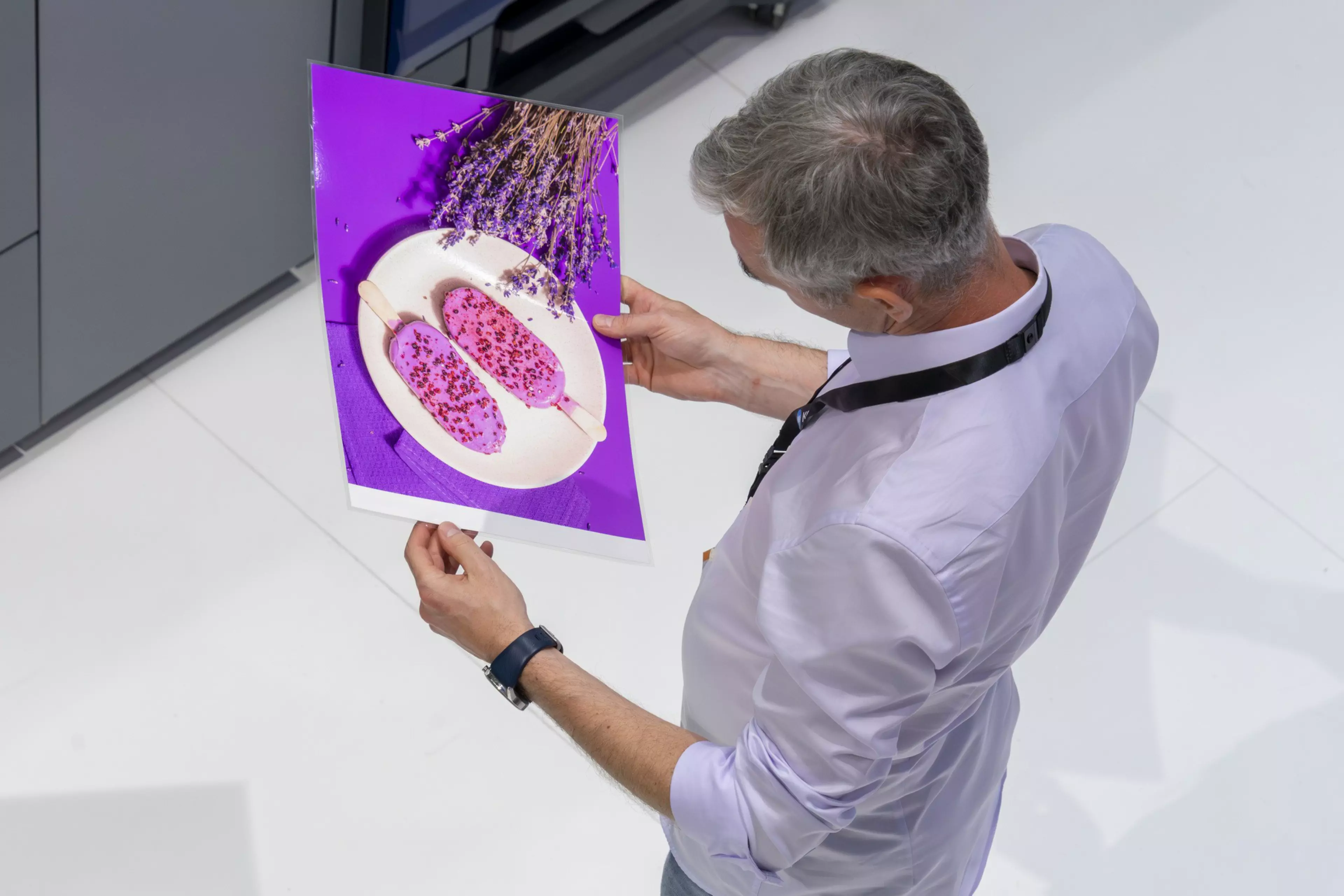

This reimagined process supports a broad choice of film sizes and types and extends the possibilities for a production of outstanding print particularly for posters, menus, flyers and covers.

Application flexibility is provided by the ability to handle paper weights from 75 gsm to 300 gsm and a wide range of different paper sizes from A4, A3 and SRA4 to SRA3. The interactive LCD panel ensures quick and easy set up as does the automatic detection of lamination foil types and sizes.

End to end inline production can be completed with the Inline Trimming Unit TU-510. It supports the one step lamination of full bleed print outs.

Pioneering technology empowers change

Jim Sawyer, Senior Director, North American Sales, ACCO Brands/GBC said: “Konica Minolta continues to pioneer innovative approaches that respond to the production demands of our customers. We are excited to share the world’s first true inline ‘lamination on demand’ solution to the market. The CL-401 is the first of its kind and only Konica Minolta can offer this combination of printing and laminating in one pass at just the touch of a button. We look forward to helping our customers dramatically change their lamination bottleneck into a process that provides quick turnarounds resulting in greater profits for their business. Konica Minolta’s CL-401 innovation from GBC is simply lamination at the speed of printing.”

The GBC CL-401 inline laminator for the Konica Minolta AccurioPress series is available now.