You wouldn't think it, but the emergence of digital printing dates back to the 1930s. But it was not until the 1970s that digital production printing became widespread. Today Konica Minolta is a market leader in the printing industry in Europe. The company offers high-quality digital solutions - including hardware, ink, software and services - that enable printing companies to offer new services and reduce costs at the same time.

The evolution of digital printing

It all began in 1938 when Chester Floyd Carlson invented electrophotography. In this form of photography, a latent image of electric charge is created from an exposed original. Ink adheres to the charged areas, which can then be used to print a copy of the original. Electrophotography (also called xerophotography) formed the foundation of the digital printing method .However, this technology did not really attract attention until sometime later.

In 1944, an American research institute became interested in electrophotography. In 1950, Haroid Xeros developed the first copying machine based on the same functional principle. The breakthrough came about ten years later with the 914 printing press model. This 300kg machine was produced more than 200,000 times in the 1970s. In the further course, machines and technology were constantly improved.

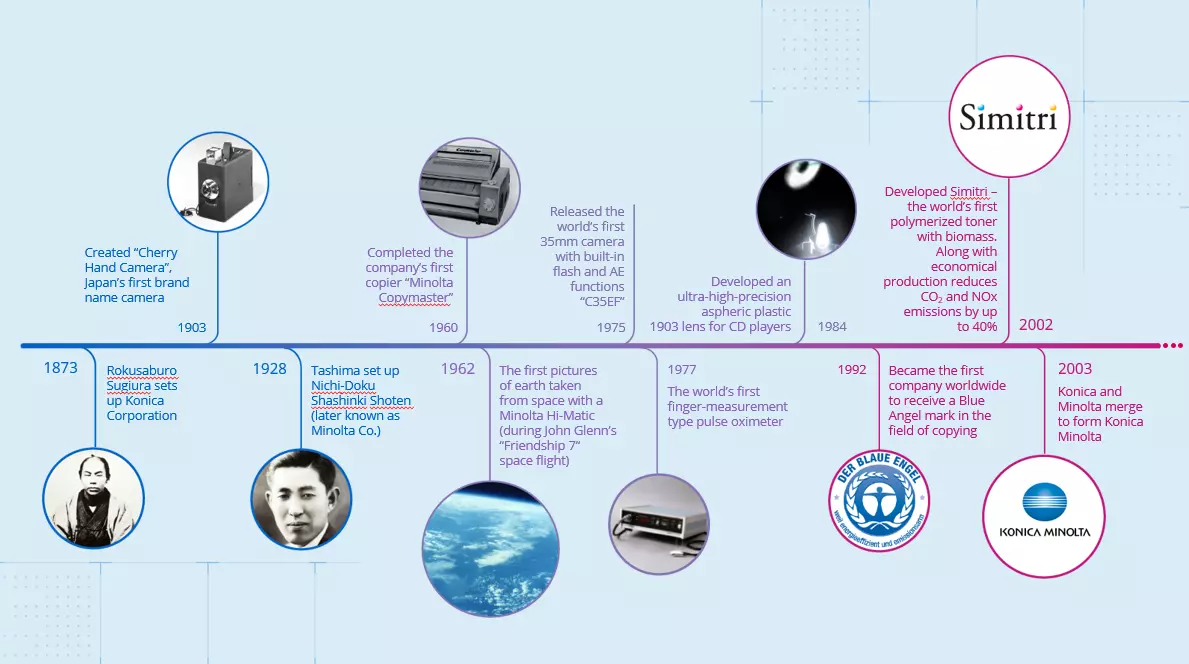

Konica Minolta's milestones on its road to success as a high-level inkjet expert

1873 - that was three years before Alexander Graham Bell filed the patent for the telephone. And six years before Thomas Alva Edison invented the electric light bulb. That was when the story of Konica Minolta began, when Rokusaburo Sugiura opened a small shop in Tokyo specialising in photographic and lithographic products. Today, more than 40,000 people work at Konica Minolta worldwide on and with market-leading technologies.

At the beginning of the inkjet business there was a vision: "If we can develop the right ink for the media, we can print on wood, glass, textile, tapestry, meta sheet and everything in the future has the possibility to become a photo media." The new possibilities were first presented to the fashion industry, where the idea to print unique textile samples hit the nerve of the industry.

Today, Konica Minolta has 40 years of experience in

inkjet printing, holds more than 12,000 patents in Japan alone, and invests 571.5 million euros annually in research and development for this field. The majority of printed textile products of worldwide leading fashion companies, even luxury brands, are printed with Konica Minolta digital textile printers.

What are the advantages of digital printing?

Unlike printing plates, in digital printing each image is created from scratch. This offers the possibility to adjust individual pages variably and to print personalized mailings or magazines.

Whereas offset is only profitable from a certain quantity onwards, with digital technology even the smallest print runs from one piece onwards can be produced in an economically viable way, such as posters and billboards. Furthermore, the possible substrates are extremely diverse. In addition to paper, many other materials can be printed on, especially in the in advertising technology. From panels and signs to tarpaulins and vinyl flooring to wallpaper.

Also, its high precision and quality with which colours and details are reproduced make digital ideal for creating high-quality print products in short runs. The faster set-up compared to offset means shortened lead times, which is particularly advantageous for short-term marketing campaigns or events.

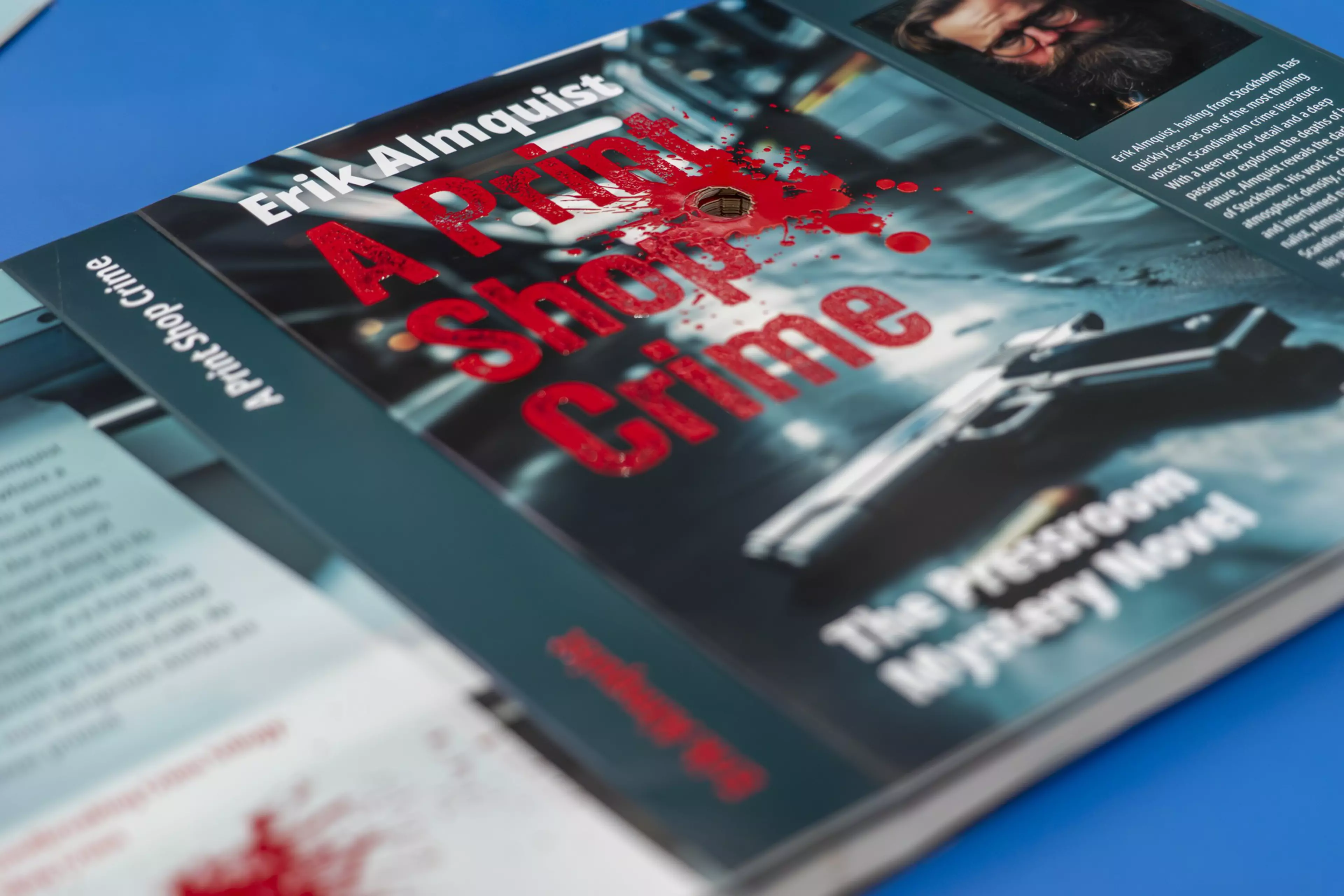

Overall, digital printing offers a cost-effective way to produce customised and professional print products in short runs without sacrificing quality. Particularly popular short-run products include flyers,

paper bags and menus.

The advantages of digital printing at a glance

- Highly flexible: no static printing form necessary; even short runs are easy to produce. can be realised without any complications.

- Wide range of applications: Modern equipment allows digital printing on numerous printing materials such as paper, wood and glass.

- Short production time: The products are usually printed within 1-2 days.

- Very individual: There are no limits to the personalisation of the desired product, such as business cards or flyers.

- High quality: Consistent print and colour quality are guaranteed.

- Cost-effective: Digital printing has a very good price-performance ratio, especially for small production quantities.

- Sustainable: Digital printing is not only flexible, but also sustainable, because no printing plates are used at all. This saves money and working time and protects the environment.

The road to becoming a leader in production printing

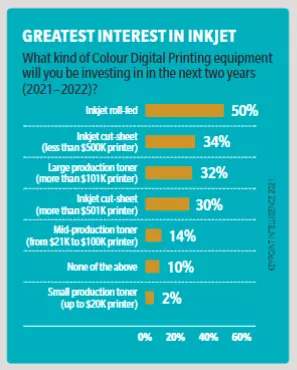

Konica Minolta successfully entered the production printing market in 2004 and is now one of the leading suppliers. In the beginning, Konica Minolta focused on the A3 cut-sheet market - today Konica Minolta is the market leader in A3 cut-sheet production printing in Europe. This demonstrates its strong commitment to innovation, quality and customer service.

As a

service provider for the production printing sector, Konica Minolta offers integrated workflows and applications as well as professional and sophisticated hardware products to help you drive your business forward .Konica Minolta help printers identify and implement new opportunities to realise savings, increase productivity, bring in new services and increase profits.

As a printer, you can benefit from these opportunities:

- Automated print production - tie in appropriate applications for automation and book production, as well as professional inline finishing equipment.

- Build on Konica Minolta hardware products, including digital technology, large format printing and maximised overall productivity.

- Take advantage of VDP's professional direct communication with solutions for variable data printing and transpromotional printing as well as cross-media communication.

- Rely on web-to-print technology and diversification.

- Optimise output control by integrating efficient colour management, make-ready and output management applications.

Konica Minolta is committed to helping you realise a fast return on investment (ROI).The printing expert provides the support and business tools you need to enter new markets. At the heart of this is a focus on print and web technologies that drive your business forward. As the digital production printing market evolves rapidly, Konica Minolta invests in research and development to provide even more innovative solutions.

Read more information here:

https://www.konicaminolta.eu/eu-en/landingpages/150-years-of-konica-minolta